What is the industrial design process?

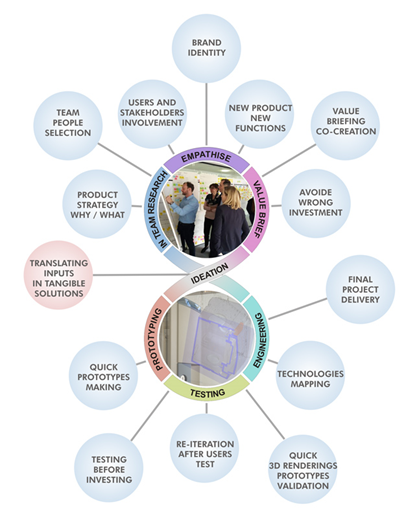

The Industrial Design process, i.e. the creation and design of a new product, is a path that develops through a series of phases that alternate situations of team collaboration with situations of study and creativity that require the maximum concentration of analysis of the needs for elaborate project proposals.

The industrial design process

1. The briefing

The exploratory phase of Design Thinking allows us to elaborate the product strategy. This is achieved by creating a team that involves the main actors (stakeholders) for example: end users, distributors, skilled workers, engineers and marketing managers. The needs of each stakeholder contribute in forming Briefing of Value. This will guide us in finding solutions to the needs and allow us to create a truly desirable product, avoiding major investment mistakes.

Today, production can involve investments of millions of Euros. Would you be comfortable spending such amounts without having a complete awareness of what is really desirable for the product you are going to produce?

2. Value Brief

With a a solid Value Brief in hand, the Industrial Designer use their creativity in seeking the best solutions to the needs that have emerged, designing a product with integrated functionality, economically viable and beautiful in its formal purity. It is clear that the Value Brief does not resemble briefings that we may see from time to time, for example, for an architect!

I would like it so!

It must be beautiful, it must be that color, but above all it must be cheap.

When submitting proposals, customer choices are often based on overly personal visions. Sometimes certain managers take it upon themselves to extend their personal vision to the entire market.

This is dangerous.

The Value Brief is an articulated document (also called a Blue print) that will help us enormously in evaluating the Design proposals in a more objective way, as we can verify if the design solutions really satisfy the wishes of the users.

3. Prototyping

Concept prototypes must be tested with the end users who provide feedback and criticism. Futher needs will likely emerge naturally in the presence of a tangible solution. All this will allow us to develop re-iterations that will bring the final solution ever closer to the needs of those who will then have to use the final product.

4. Project optimization

At this point we move on to the optimization of the project, making it compatible with the mechanics and internal electronics and above all ensuring it can be produced with the appropriate technologies.

5. Final product engineering

Upon approval of the optimized solution, we come to the final step of the Industrial design process: the engineering of the finished product. This must respect the Design intentions that bring Value to the product, otherwise, bad or superficial management of the Engineering can render all efforts useless and betray the developed solution.

The engineering, whether developed by the Designer or developed by the Customer’s Technical Department, cannot do without the supervision of the Designer. Unfortunately, it sometimes happens that customers eclipse themselves during engineering and then arrive with a completely distorted product and thus fall back into the risk of an bad investment.